In auto body shops and collision centers, where noise and respiratory hazards are prevalent, proper use of technician safety equipment like respirators, ear protection, and protective clothing is crucial for mitigating risks of hearing loss (NIHL) and respiratory issues such as asthma and COPD. This equipment fosters safer work environments, enabling technicians to operate high-decibel machinery and handle hazardous materials effectively while protecting their health.

In today’s industrial landscape, technicians face a dual threat from noise pollution and respiratory hazards. This article explores how technician safety equipment (TSE) serves as a robust shield against these dangers. We delve into the intricate world of noise and respiratory risks prevalent in technical environments, highlighting the critical role TSE plays in worker protection. From earplugs to specialized respirators, discover the key components enhancing safety measures and ensuring healthier work conditions for technicians.

- Understanding Noise and Respiratory Hazards in Technical Environments

- The Role of Technician Safety Equipment in Mitigation

- Key Components and Their Effectiveness Against Noise and Respiratory Risks

Understanding Noise and Respiratory Hazards in Technical Environments

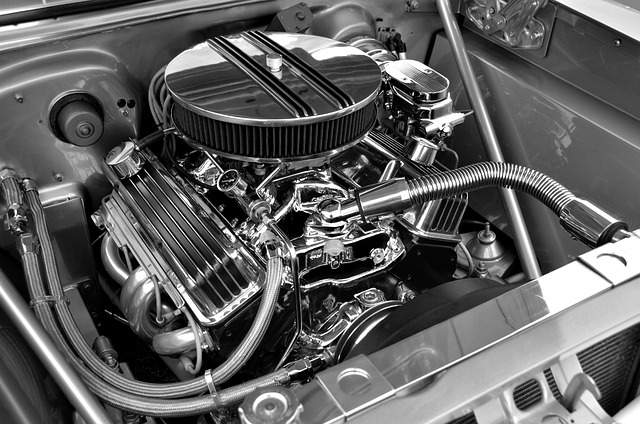

In technical environments, both noise and respiratory hazards are prevalent risks that can significantly impact technicians’ health and well-being. Noise exposure is a common issue in many industrial settings, including auto body shops and car restoration facilities. The constant hum of machinery, grinding sounds, and high-decibel tools can lead to hearing damage over time. Prolonged exposure may result in conditions like noise-induced hearing loss (NIHL), which can affect communication and overall quality of life.

Respiratory hazards are equally concerning, especially in auto body repair and similar trades. Technicians often work with hazardous materials, such as paints, solvents, and fumes from welding or sandblasting processes. Inhaling these substances can cause respiratory issues, including irritation of the nose and throat, asthma, and even more severe conditions like chronic obstructive pulmonary disease (COPD). Proper use of technician safety equipment, including respirators and protective clothing, is crucial to mitigate these risks and ensure the health and safety of workers in these technical environments.

The Role of Technician Safety Equipment in Mitigation

Technician safety equipment plays a pivotal role in mitigating noise and respiratory hazards that are prevalent in automotive environments, such as car body repair shops and vehicle body shops. These hazards can range from harmful particles and fumes to damaging sound levels, posing significant risks to workers’ health over time. Proper safety gear, including respirators, ear protection, and specialized clothing, acts as a barrier between technicians and these dangers.

In the fast-paced world of automotive collision repair, where metal banging and paint spraying are common, technician safety equipment ensures that workers can perform their duties without compromising their well-being. For instance, noise reduction earpieces or full-face respirators protect against deafness and respiratory issues caused by excessive noise and toxic chemicals, enhancing the overall safety of the workshop environment.

Key Components and Their Effectiveness Against Noise and Respiratory Risks

Technician safety equipment plays a vital role in protecting workers in various industries, including automotive repairs and collision centers. Key components like noise-canceling ear protection and respirators are designed to combat two significant hazards: noise exposure and respiratory risks. These devices are highly effective in creating a safe environment for technicians, who often work in bustling settings with high-decibel machinery.

For instance, noise-canceling earplugs or earmuffs can block or significantly reduce damaging sound waves, preventing long-term hearing loss. Similarly, respirators equipped with filters and sealed masks ensure that workers breathe clean air, protecting against hazardous particles, fumes, and gases commonly found in vehicle body repair processes. This equipment not only enhances individual protection but also contributes to a healthier work environment overall within these high-risk industries.

Technician safety equipment plays a pivotal role in protecting workers from noise-induced hearing loss and respiratory hazards. By understanding the specific risks present in technical environments, we can equip technicians with the right tools. Through the use of specialized gear, such as earplugs, respirators, and protective clothing, professionals can mitigate these dangers effectively. These simple yet powerful measures ensure that technicians can perform their duties safely, maintaining their well-being and preventing long-term health issues associated with exposure to noise and harmful substances.