Adopting ergonomic practices in bumper repair and car restoration is crucial for technicians, aiming to boost efficiency and reduce physical strain. Utilizing appropriate technician safety equipment like adjustable workstations and ergonomic tools helps maintain neutral body positions, decreasing the risk of musculoskeletal disorders (MSDs). This not only improves job satisfaction but also prevents long-term health issues associated with auto bodywork. Integrating this equipment strategically creates a safer, more productive environment, fostering a culture of ergonomic excellence while mitigating risks beyond compliance standards.

Technician safety equipment is more than just protective gear; it’s a vital tool in promoting ergonomic work practices. As technicians navigate complex tasks, proper equipment can significantly reduce physical strain and improve overall workplace comfort. This article explores the interconnectedness of technician safety equipment and ergonomics, delving into strategies that foster a safe and efficient workspace. We’ll discuss why this approach is crucial for both technicians’ well-being and organizational success.

- Understanding the Importance of Ergonomic Work Practices for Technicians

- The Role of Technician Safety Equipment in Promoting Ergonomics

- Best Practices for Integrating Safety Equipment into Ergo-Friendly Workspaces

Understanding the Importance of Ergonomic Work Practices for Technicians

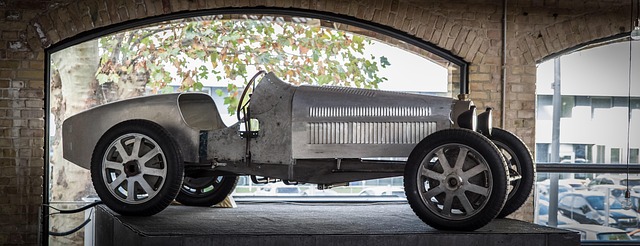

For technicians working in fields like bumper repair or car restoration, adopting ergonomic work practices is more than a recommendation—it’s a necessity. These professionals often spend hours performing intricate tasks that demand precision and endurance. Using the right technician safety equipment plays a pivotal role in promoting ergonomic work, reducing the risk of musculoskeletal disorders (MSDs) that can arise from repetitive motions and awkward postures.

By prioritizing ergonomic principles, technicians can enhance their efficiency while minimizing physical strain on their bodies. This is especially crucial in car bodywork, where precision and safety are paramount. Suitable technician safety equipment, such as adjustable workstations or ergonomic hand tools, ensures that workers maintain neutral body positions, reducing the load on joints and muscles. In turn, this translates to increased job satisfaction, improved productivity, and a lower likelihood of long-term health issues related to work activities.

The Role of Technician Safety Equipment in Promoting Ergonomics

Technician safety equipment plays a pivotal role in promoting ergonomic work practices within auto repair shops and car bodywork services. By prioritizing worker safety, this equipment ensures that technicians can perform their tasks without risking musculoskeletal injuries often associated with repetitive motions and heavy lifting. From robust gloves and protective eyewear to specialized tools designed for comfort and efficiency, each component contributes to creating a safer and more ergonomically sound environment.

For instance, in tire services, the use of ergonomic hand tools reduces strain on technicians’ wrists and arms, while properly fitted safety gear minimizes the risk of injury during hazardous tasks. This not only enhances worker well-being but also boosts productivity by preventing costly absenteeism due to work-related injuries. In essence, integrating technician safety equipment is not just a matter of compliance; it’s a strategic investment in fostering a culture of ergonomic excellence within these industries.

Best Practices for Integrating Safety Equipment into Ergo-Friendly Workspaces

When integrating technician safety equipment into ergonomically designed workspaces, best practices involve a holistic approach that prioritizes both worker comfort and task efficiency. Begin by assessing the specific tasks performed in the workspace and identifying potential hazards, such as repetitive motions or exposure to harmful substances. Based on this assessment, select safety equipment that aligns with industry standards and provides adequate protection without compromising dexterity or mobility.

Implement a structured organization system for storing and retrieving safety gear, ensuring it is easily accessible yet out of the way during active work areas. Encourage regular use by fostering a culture of safety awareness, where technicians are trained to put on their protective equipment as second nature. Additionally, consider incorporating ergonomic tools and workstations alongside technician safety equipment to optimize comfort and minimize physical strain in vehicle body shops or auto body work environments.

Technician safety equipment plays a pivotal role in fostering ergonomic work practices, ultimately enhancing the well-being and productivity of technicians. By incorporating these specialized tools into their daily routines, organizations can create safer and more comfortable work environments. Adopting best practices for integration ensures that safety doesn’t compromise efficiency but rather complements it, allowing technicians to perform their tasks with reduced strain and increased satisfaction. This, in turn, contributes to a healthier workforce and improved overall job performance.